Comparison of Different Types of Steel Used in Hair Cutting Shears Based on Their Hardness

What are the effects of using hard steel in hair shears? The hardness of the steel used in the manufacture of shears affects not only the blade edge and how long it will remain sharp, but also the shears' lifespan and ability to withstand wear and tear.

The Blade Edge of Your Hair Shears

The type of steel used to make scissors will have an impact on the blade edge, which is critical. Honing cannot produce a fine edge on steel that is of poor quality or soft. Only high-quality steel shears will give you a razor-sharp edge on your scissors, allowing you to cut through hair with minimal effort while still achieving a clean cut.

What is the Rockwell Scale?

The Rockwell Hardness scale is used to determine the toughness of a material. It allows manufacturers to maintain quality control while also providing customers with some clarity about the product they are purchasing.

To determine the hardness of a material, the test is applied to a wide range of metals and alloys, including steel used in shears and scissors. The depth of penetration is measured using a diamond-tipped indenter while under heavy load.

The higher the number, the higher the quality of the steel in terms of hardness and edge retention. A soft steel will have an HRC rating of 54-56, whereas a premium hard steel will have a rating of 59-66. HRC is frequently abbreviated to RC after a number before being written out in full. Shears and scissors should be made of high-quality steel with a Rockwell Hardness measurement between 58 and 60 RC.

How long will the shears last?

The durability of the scissors is directly proportional to the quality of the steel used in their manufacture. Shears used in hairdressing should be sharpened at least once a year. A bladesmith will also need to remove a small amount of steel from the blade in order to sharpen it. Because higher-quality steel requires less material to be removed, cheaper pairs of knives can only be sharpened a certain number of times.

What is it about steel that makes it so difficult to work with?

Shears cannot be made from a single material because steel is an exact blend of various alloys, ores, and elements. Steel's strength is due to carbon, and the amount of carbon in the finished product should be between.95 and 1.2%. Even though shear steel should be hard, it should not be too hard because it will not be suitable for dry or slide cutting.

Molybdenum contributes to the hardness of materials as well as their corrosion resistance. Shears are prone to corrosion because they are constantly in contact with water and the chemicals used in color treatments. If the steel used in the shears did not contain molybdenum, it would be pitted and dull.

Manganese contributes to the overall strength of the blade and aids in the maintenance of a sharp, long-lasting edge. Chromium contributes to increased heat resistance during the forging and finishing processes, and it also contributes to increased corrosion resistance when the shears are in use. Vanadium adds strength and helps the scissors keep their set while also aiding in balance.

Both cobalt and titanium reduce the weight of finished shears while increasing their hardness.

Steel Types Used in Barber Shears

A grade can be assigned to any type of steel based on the proportions of the various components used in its manufacture.

In Pakistan, the 420 grade is used to make low-cost scissors, whereas in Japan, the 440C grade is used to make more expensive scissors. The Rockwell rating for 420 stainless steel is 50 to 55, while the Rockwell rating for 440 cobalted stainless steel is 55 to 62. This is a significant difference.

The S1 has a low cobalt steel content, giving it a hardened shear, whereas the S3 has a high cobalt steel content, giving it a sharp cutting edge. Vanadium and titanium are two materials that can be added to blades in the V category to increase their strength and sharpness.

The ATS-314 has a Rockwell rating of 59-61 and the highest concentrations of cobalt, titanium, and vanadium of any alloy.

A high-quality steel product necessitates not only high-quality raw materials, but also high-quality craftsmanship and an optimal steel tempering process.

Steel VG10

VG10 stainless steel is a higher grade of stainless steel manufactured in Japan. It is also known as cutlery grade because it was designed with Japanese chefs in mind. The letter V represents the chemical element vanadium, and the letter G represents gold, which indicates its quality.

VG10 has a Rockwell Hardness ranging from 59 to 61 due to its high carbon and cobalt content. The VG10 shears are known for their high level of durability and for having a blade that stays sharp for the life of the shears. Sharpening VG10 to a finer point is possible than with many other types of steel. At some point, the VG10 was renamed the SuperSteel. Check out this collection of VG10 Offset Scissors.

Saki Shears has created the Master collection of hair shears to make it easy to identify the hair shears utilizing VG10 steel or the quality equivalent. Current models include our Gold Hair Cutting Scissors, Grand Master Hair Shears and Saki Precision.

Steel of Damascus

Damascus steel is made by folding 15-17 times thin layers of high-quality VG10 steel onto themselves, resulting in approximately 5,000 very thin layers of steel. The layering technique creates the appearance of fine wood grain or a water mark on the surface of the shears. Multiple layers are used to achieve this effect.

The primary benefit of using layered steel is that it allows the shears' blades to be sturdy while remaining flexible and gentle when in contact with one another.

Saki Shears currently has three shear models that utilized Damascus steel in their production. All three shears are part of our Shihan collection.

- Saki Dotanuki Damascus Hair Shears

- Saki Kodachi Damascus Hair Shears

- Saki Kamakura Damascus Hair Shears

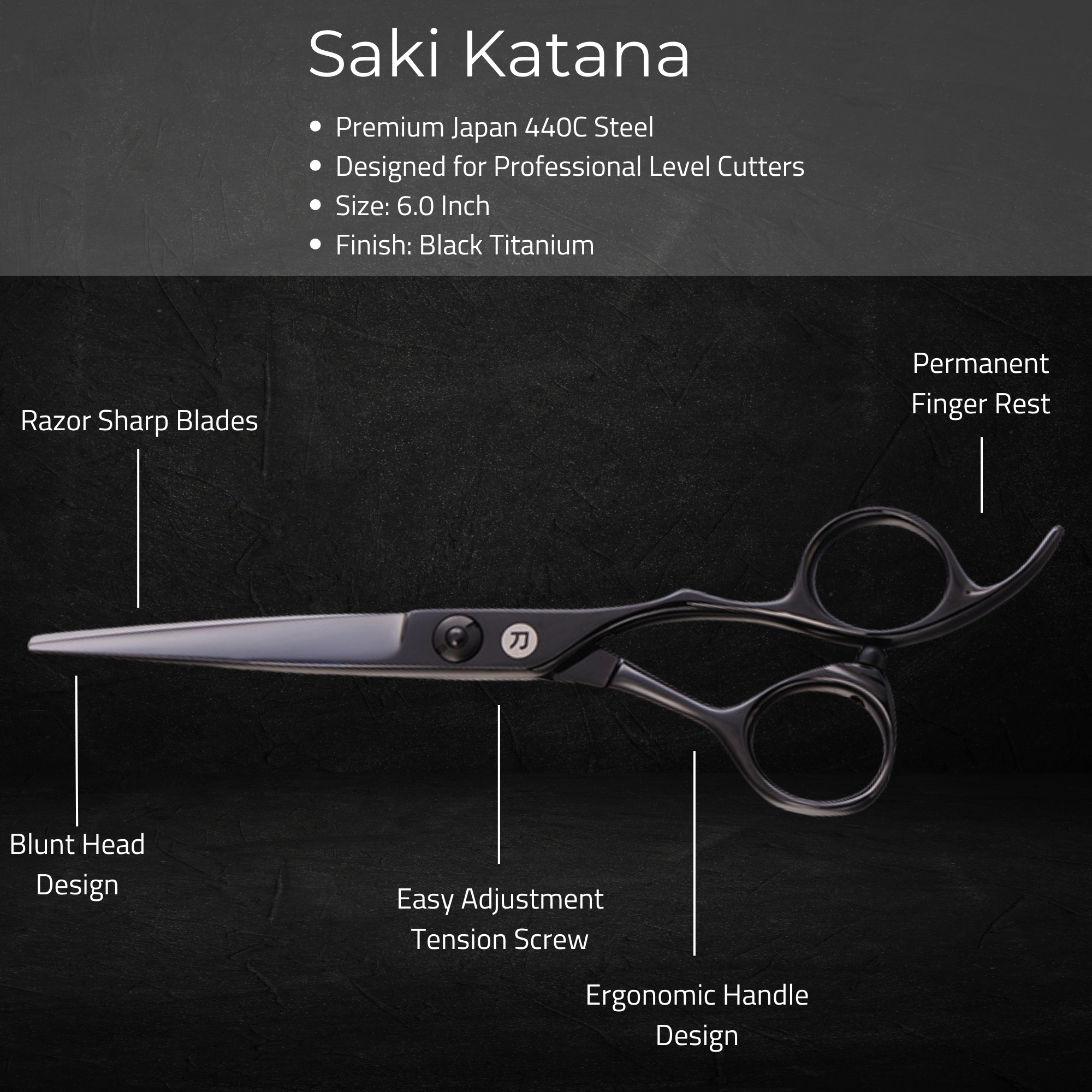

Steel Grade 440C

Because it has the highest carbon content of any steel grade, 440C steel is among the most expensive steels available. It is also one of the hardest steels in the 440 family.

A few of the most popular Saki Shears cutting scissors that utilize 440C steel in their construction include our new Saki Tano Hair Shear, and the Saki Odachi Hair Cutting Scissors.

Which countries are the primary steel producers?

Saki Shears almost exclusively uses Japanese steel in its hairdressing scissors. Because the Japanese have mastered the art of producing steel, no other country in the world can match the incredible quality produced by Japanese steel manufacturers. Germany is the world's second-largest steel producer, trailing only China.

Their steel is extremely hard; in fact, sharpening it to a razor's edge is impossible; however, it is an excellent choice for barbering scissors with a bevel edge.

Aside from Korea, three other countries that produce steel are China, Taiwan, and Korea. Their steel is not as hard as Japanese steel and does not maintain its edge as well. India and Pakistan are the other two countries that manufacture this item.

Their steel is not suitable for use in professional shears due to its low quality because it is difficult to sharpen and does not retain its edge.

Steel Aichi

Aichi Steel is one of the world's leading producers of high quality steel. Their steel is used in a wide range of industries and is of very high quality. They started as a division of Toyota in 1934.

Hitachi Metals Corporation

Hitachi Metals was founded in Japan in 1956, and the company has been dedicated to producing high-quality steel blades and other products for use in the automotive, infrastructure, and electronics industries ever since. Hitachi is in charge of producing the highest grade of Japanese steel, known as ATS-314.